The Importance of HVAC Duct Systems

With the development of construction projects, HVAC (Heating, Ventilation, and Air Conditioning) systems have become increasingly important in ensuring indoor comfort and a healthy environment. As a key component of these systems, the construction technology and selection of suitable ducts are crucial for the system's operational effectiveness. This article aims to summarize the construction techniques for HVAC ducts in building projects and explore their characteristics. By conducting in-depth research, it is hoped to provide reference and guidance for industry professionals, helping them better conduct duct construction and choose appropriate duct types to ensure smooth HVAC system operation.

Characteristics of HVAC Ducts

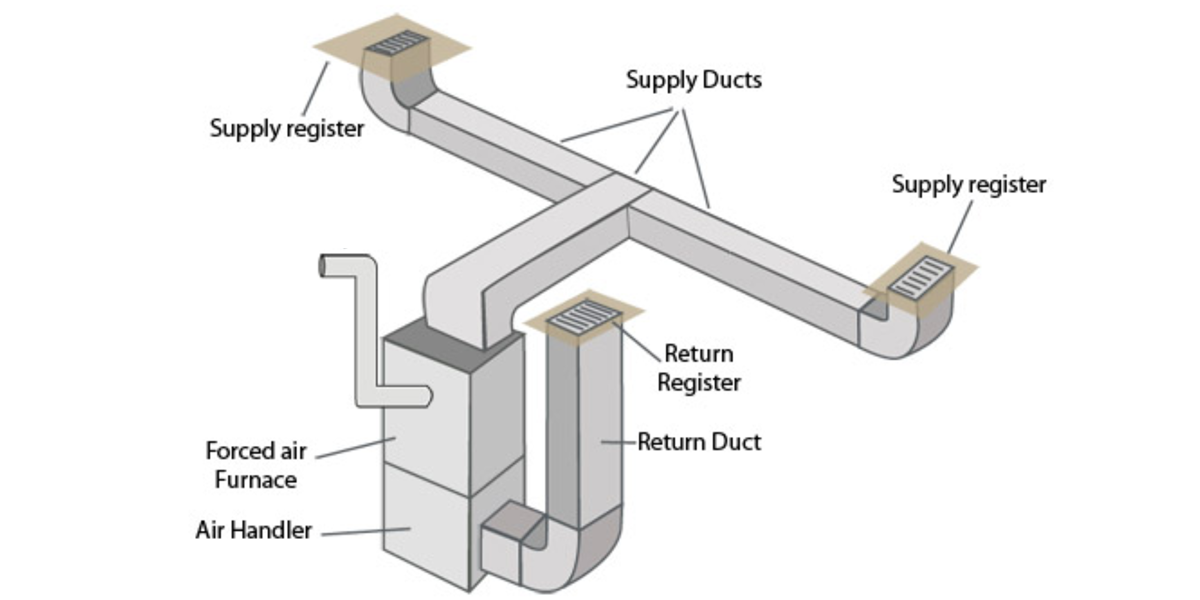

HVAC ducts are important components of buildings used to transport air, heat, and humidity. They play a key role in providing a comfortable temperature, fresh air, and appropriate humidity indoors. The following are the characteristics of HVAC ducts:

- Ventilation Function: The HVAC duct system exchanges and circulates fresh air and expels stale air, improving indoor air quality, reducing the accumulation of harmful substances, and maintaining a fresh indoor environment.

- Heating and Cooling Function: In winter, the duct system can transport heated air to provide comfortable indoor temperatures. By controlling air flow speed and temperature, ducts can achieve precise temperature control in different rooms, improving energy efficiency.

- Safety and Durability Requirements: HVAC ducts are designed with special materials and structures to meet safety, durability, soundproofing, and fire resistance requirements. The system must account for air resistance, pressure loss, and other factors to ensure effective airflow within the ducts.

- Rational Layout and Stability: HVAC ducts must be arranged reasonably according to the building's structure and functional requirements. The ducts should avoid collisions with other equipment and structures to ensure system stability and safety.● Energy Efficiency and Environmental Benefits: The HVAC duct system can reduce energy consumption by optimizing design and adopting

energy-saving measures. For instance, high-efficiency heat exchangers and energy-saving fans can be used to minimize energy loss. In recent years, pre-insulated duct, a new type of duct material, have been widely used in modern HVAC systems due to their excellent thermal insulation properties. Pre-insulated ducts not only effectively reduce energy loss but also minimize condensation issues, enhancing the overall efficiency of the system.

In conclusion, HVAC ducts are indispensable parts of buildings, playing a crucial role in the transmission of air, heat, and humidity. Their characteristics include ventilation, heating and cooling, duct design and layout, energy efficiency, and automation control. With proper design and operation, HVAC ducts can create a favorable indoor environment and improve people’s quality of life.

HVAC Duct Construction Technology in Building Projects

1. Preliminary Preparations

Before duct construction, the design plan should comprehensively consider factors such as airflow, wind speed, duct diameter, and materials, following relevant standards for calculations and selection. A reasonable duct plan can ensure the efficient operation and comfort of the system. Once the plan is finalized, the necessary duct materials, including metal, non-metal, and insulation materials, should be determined. Material selection should be based on design requirements and the specific environment. For example, high-temperature environments require high-temperature resistant materials, while humid environments require corrosion-resistant materials. During procurement, attention should be paid to whether the materials meet the required quality and specifications, and proper stock should be kept to ensure smooth construction.

Construction personnel must possess necessary skills and knowledge, familiar with relevant processes and operating procedures. They should understand proper duct installation methods, joint treatments, insulation material installations, etc. Training sessions or professional institution support may be organized to enhance the professional level of construction workers and ensure quality construction.

2. Duct Layout and Support Installation

First, during duct layout, the location of the ducts should be determined according to the design plan, with dimensions and height clearly marked. This ensures the ducts meet both design and building structure requirements. Additionally, the layout should avoid key structural components and other pipelines to ensure smooth airflow and aesthetic quality.

Next, the type and spacing of supports should be determined. Different types of ducts may require different types of supports. To ensure the supports are stable and reliable, appropriate support materials should be selected based on the duct material's characteristics. When choosing supports, the weight of the duct and the working pressure must be considered to ensure the supports can bear the required load.

Before installing the supports, a strength test on the building structure should be conducted to ensure the installation does not affect the structural safety of the building. Strength testing will determine the support locations, installation methods, and whether reinforcement is needed.

The installation of supports must be firm and reliable to prevent any loosening or tilting during use. To achieve this, the correct selection and installation of support brackets are necessary. Support brackets must be capable of withstanding the weight and pressure of the duct and connect to the ducts through appropriate methods. Additionally, the supports should be treated for corrosion resistance to prolong their service life.

3. HVAC Duct Fabrication and Installation

When fabricating and installing ducts, materials must be cut, bent, welded, and processed as per the design plan and actual requirements to produce ducts that meet the required dimensions and shapes. To ensure tight connections and sealing, appropriate connection methods such as welding, threaded connections, and flange connections should be used.

During installation, duct should be installed section by section onto the supports according to the layout plan, ensuring the ducts' level and verticality to guarantee stability and normal operation. At the same time, care should be taken to avoid bending, twisting, or damaging the duct to ensure their integrity and safety.

Für pre-insulated duct, particular attention should be paid to the sealing of joints. Since pre-insulated duct have excellent thermal insulation properties, their joints, elbows, and other connections should be sealed to minimize energy loss.

4. Insulation and Protection

Insulation and protection reduce energy loss and prevent condensation. When selecting insulation materials and protecting duct, several key factors should be considered to ensure construction quality and system reliability.

Common insulation materials used for duct include polyethylene foam, mineral wool, and glass wool. Choosing the right insulation material is essential for achieving the desired insulation effect. The thermal conductivity of the material determines its insulation performance, with lower conductivity leading to better insulation. In high-temperature environments, the fire resistance of insulation materials is crucial.

The durability of the insulation material directly affects its service life. Selecting long-lasting materials reduces the frequency of maintenance and replacement. Environmental impact should also be considered when selecting insulation materials, with priority given to eco-friendly, non-toxic, and pollution-free options.

Additionally, the thickness of insulation materials should be chosen according to the duct size and project requirements. By calculating heat loss and energy-saving effects, the optimal thickness can be determined to achieve the expected insulation effect.

At GFI HVAC, our advanced pre-insulated duct panels deliver superior thermal insulation performance, ensuring energy efficiency and enhanced system reliability for commercial and industrial HVAC projects. Our panels are manufactured with high-quality PIR and PU foam cores combined with protective coatings, offering excellent thermal conductivity and moisture resistance. Their lightweight yet durable design reduces installation time and maintenance efforts, making them an optimal choice for energy-saving HVAC solutions.

5. Testing and Debugging

Testing and debugging ensure the quality and proper functioning of the entire system. Leak testing is an essential step to check whether the duct connections are firm and leak-free. Before testing, all valves and fans should be closed, and the control system's interference removed. Then, appropriate methods should be used to pressurize the system to verify whether any leaks are present. Pressure gauges and visual inspection of the joints can help determine if there are any leaks.

Air tightness tests ensure the entire duct system is sealed well to avoid energy loss and unnecessary air movement. Before testing, all fans and valves should be closed, and the system should be in a stationary state. Then, air testing instruments should be inserted at suitable points to check the system’s air tightness. If the test shows no leaks, the system can be confirmed to meet the air-tightness standard.

During debugging, system parameters like airflow, wind speed, and temperature should be checked to ensure they meet design requirements. Technicians must examine each component's operation and adjust parameters to optimize the system's performance.

Abschluss

The construction technology of HVAC ducts in building projects is crucial for ensuring system stability, improving indoor air quality, and enhancing comfort. Through proper design, material selection, construction, and testing, the operational effectiveness and economic benefits of the ducts can be maximized. To achieve this, careful consideration must be given during the design phase to ensure quality control at every stage.

As a leading provider of HVAC solutions, GFI Duct is committed to delivering high-quality HVAC ducts and components to global customers. We offer comprehensive support from design to construction, from material selection to installation, ensuring that every project runs smoothly and achieves optimal results. Whether it's PIR pre-insulated ducts, aluminum foil-lined ducts, or various duct accessories, GFI Duct leverages years of industry experience to provide innovative, energy-saving solutions. In the future, we will continue to adhere to a quality-first principle, constantly optimizing our products and services to support the success of more building projects.

As HVAC duct construction technology progresses, it is essential to continue focusing on technological advancements and environmental protection to enhance system intelligence, energy efficiency, and environmental performance. Choose GFI Duct, and you’ll have a reliable partner to drive the industry's growth.