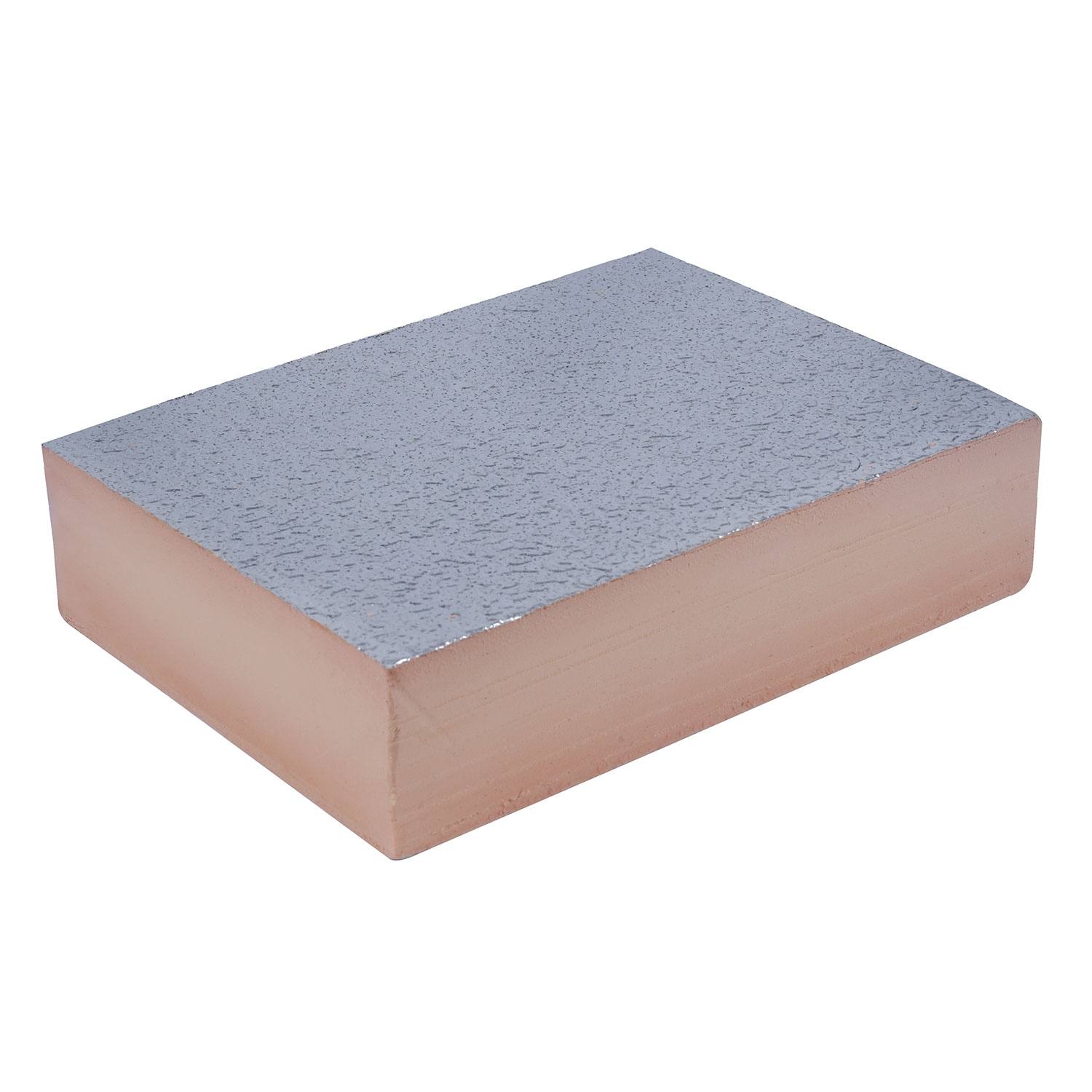

Phenolic Foam Insulation Board with Aluminum Foil

Thickness : 20-100mm

Facing material : 80micron aluminum foil

Density : 40-60 kg/m3

Size : 1.2 m / 0.6m width, length can be customized

Email Address:sales@gfiduct.com

Phenolic Foam Insulation Board with Aluminum Foil

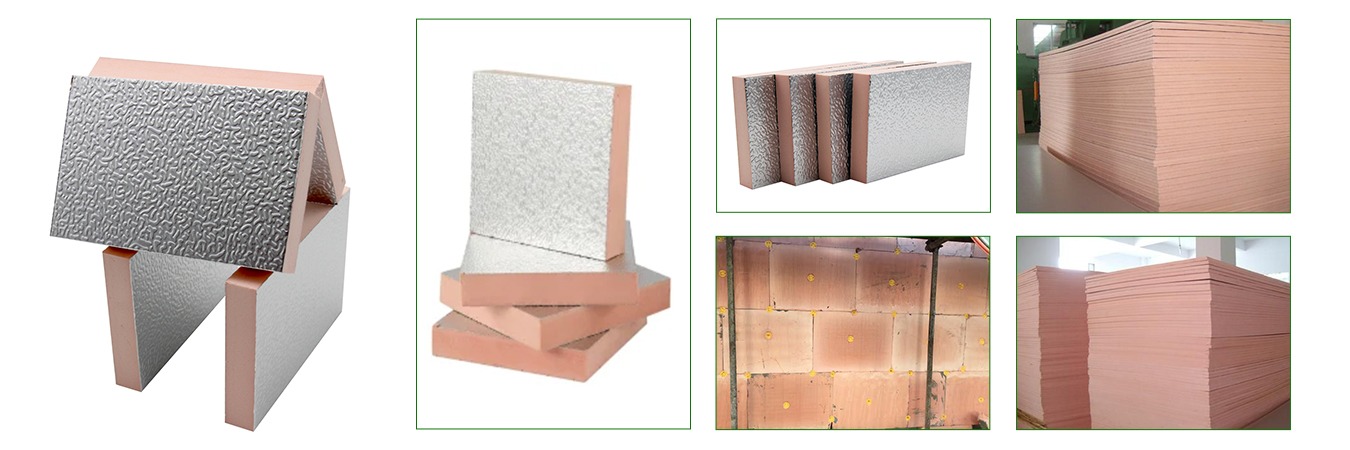

Phenolic Foam Insulation Board with aluminum foil is a versatile and high-performance insulation material commonly used in construction and industrial applications. Phenolic Duct Board consists of a Phenolic Foam Insulation core sandwiched between layers of aluminum foil, providing excellent thermal insulation properties along with moisture and vapor resistance. The Phenolic Foam Insulation Fire Rating is best.

Technical Data Sheet

| Property | Standard | Specification |

| Standard Width | 600/1200mm | |

| Thickness | 20-100mm | |

| Foam Density | 40-60kg/m³ | |

| CFCs and HCFCs | Headspace GC/MS | Free |

| Thermal Conductivity | 0.02W/m.K | |

| Fire Rating |

BS 476 ASTM E-84 UL94-1998 |

Class 0 Class A 94V-0 |

|

Water Vapor Transmission (at 23°C, 50% R.H., 8.26mm thickness, 12 days) |

ASTM E96-05 | 0.05g/hr/Sqm |

| Water Absorption (% by volume) | ASTM C209-98 | 0.25 |

| Compressive Strength | ASTM D1621-00 | 137.7psi |

| Dimensional Stability | ASTM D 2121-99 | 0.3% |

| Tensile Strength | ASTM D1623-00 | 61.4psi |

Advantages of Phenolic Foam Insulation Board

01 / High Thermal Insulation Efficiency: Phenolic Foam Board has a low thermal conductivity, offering superior insulation performance compared to other traditional insulation materials.

02 / Moisture and Vapor Resistance: The aluminum foil facing and kraft paper act as a barrier against moisture and vapor ingress, preventing water penetration and ensuring long-term insulation effectiveness.

03 / Fire Resistance: Phenolic Foam Duct Board is inherently fire-resistant, and when combined with the aluminum foil and kraft paper facing, it provides an added layer of protection against flames and heat spread. This makes it suitable for applications requiring fire safety compliance.

04 / Lightweight and Rigid: Phenolic Foam Insulation are with lightweight, making them easy to handle and install. They maintain their shape and structural integrity even under compression, ensuring long-term performance.

05 / Chemical Stability: Phenolic Foam Board is resistant to most chemicals, acids, and alkalis, making it suitable for use in harsh industrial environments and chemical processing facilities.

06 / Sound Insulation: Phenolic Foam insulation absorbs and dampens sound waves, providing effective noise reduction in buildings and machinery enclosures.

Application of Phenolic Insulation Board

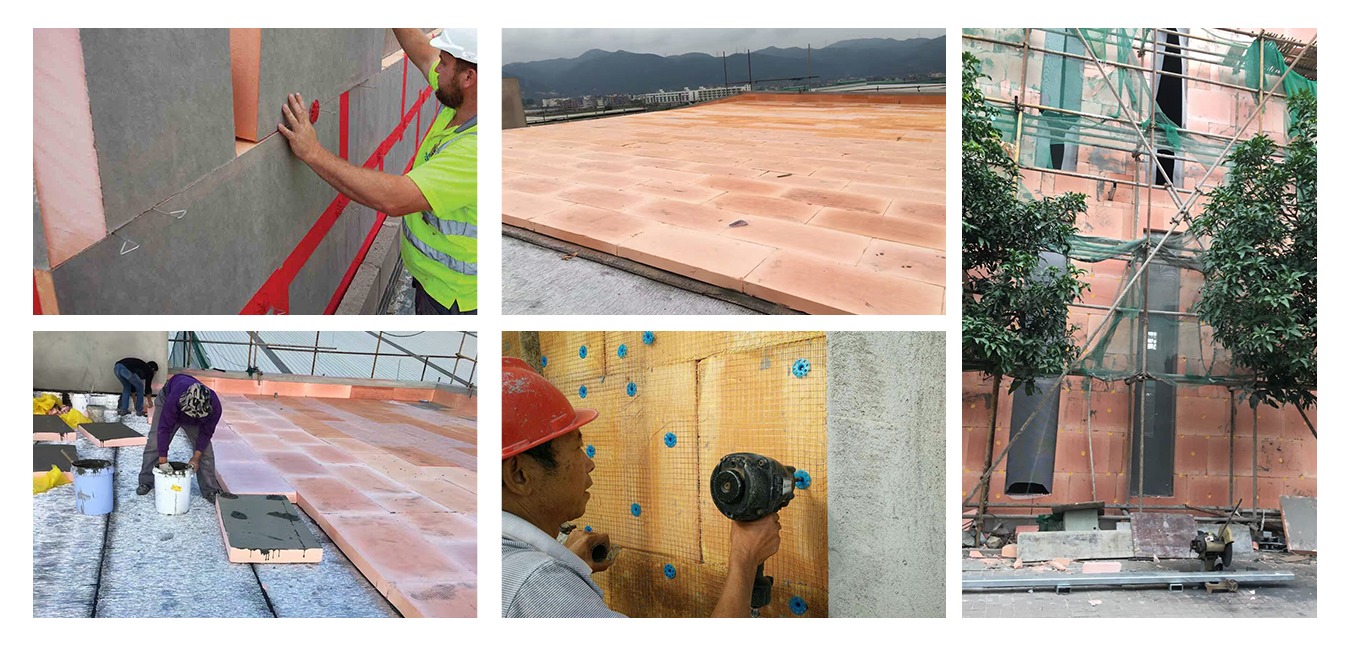

1.Wall Insulation Systems

- External Thermal Insulation Composite Systems (ETICS) : Phenolic Foam Insulation Boards serve as the primary insulation layer installed on the exterior walls of buildings, providing thermal insulation and reducing heat transfer through the walls.

- Internal Wall Insulation Systems : Used for insulating the internal walls of buildings, particularly suitable for retrofitting old buildings for energy efficiency without affecting the exterior appearance.

2.Roof Insulation

- Flat Roof Insulation : Phenolic Foam Roof Insulation can be directly laid on flat roofs, creating a continuous insulation layer to prevent heat loss through the roof.

- Pitched Roof Insulation : Suitable for various forms of pitched roofs, easy to install, and enhances overall insulation performance.

3.Floor Insulation

- Underfloor Heating Systems : In underfloor heating systems, Phenolic Insulation Board effectively reduce downward heat loss, improving the energy efficiency of the heating system.

- General Floor Insulation : Used in regular floor structures to enhance insulation performance and improve indoor comfort.