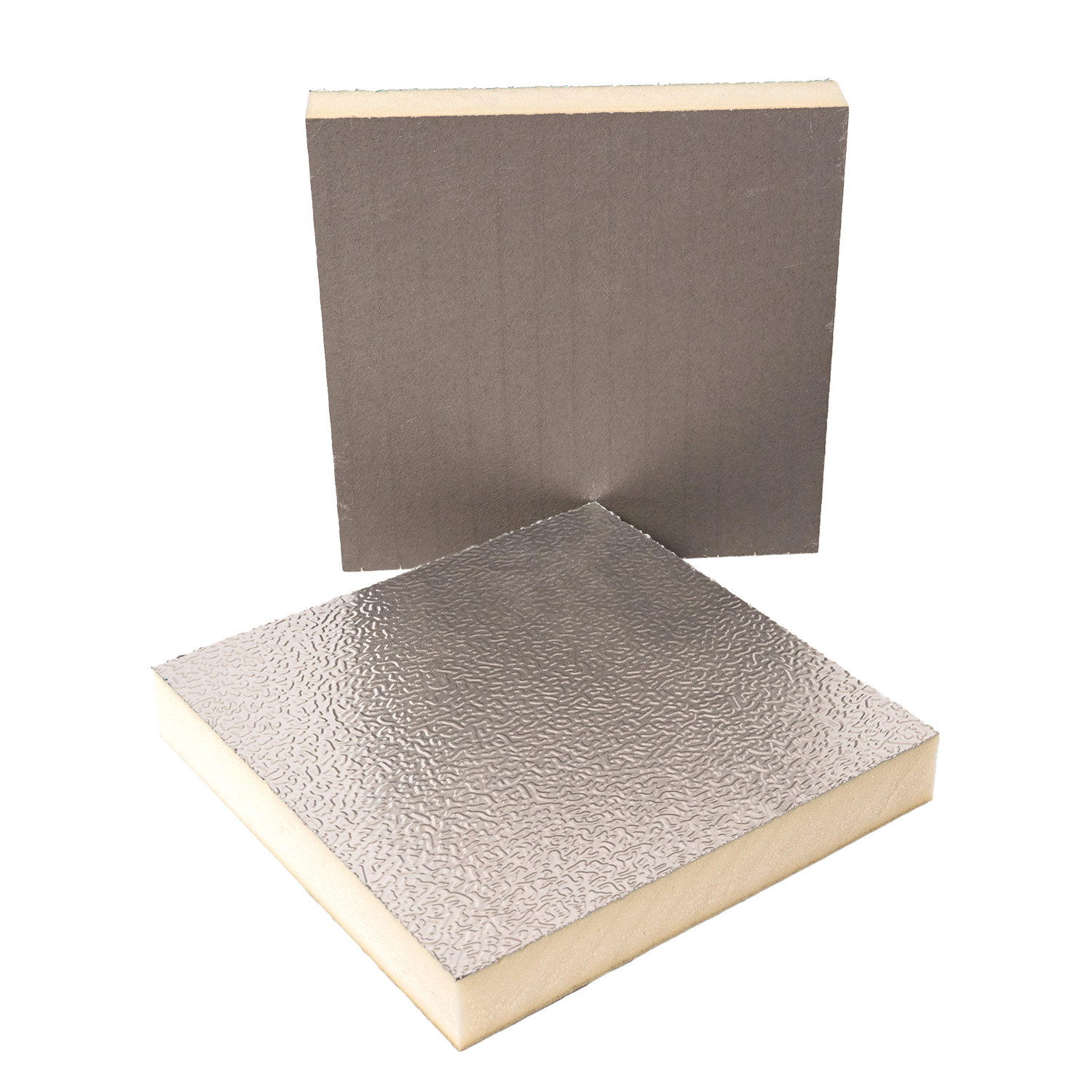

PU Foam Board with Aluminum Foil

Thickness : 10-80mm

Facing material : 80micron aluminum foil

Density : 30-50 kg/m3

Size : 1.2 m / 0.6m width, length can be customized

Email Address:sales@gfiduct.com

Polyurethane Foam Board with Aluminum Foil

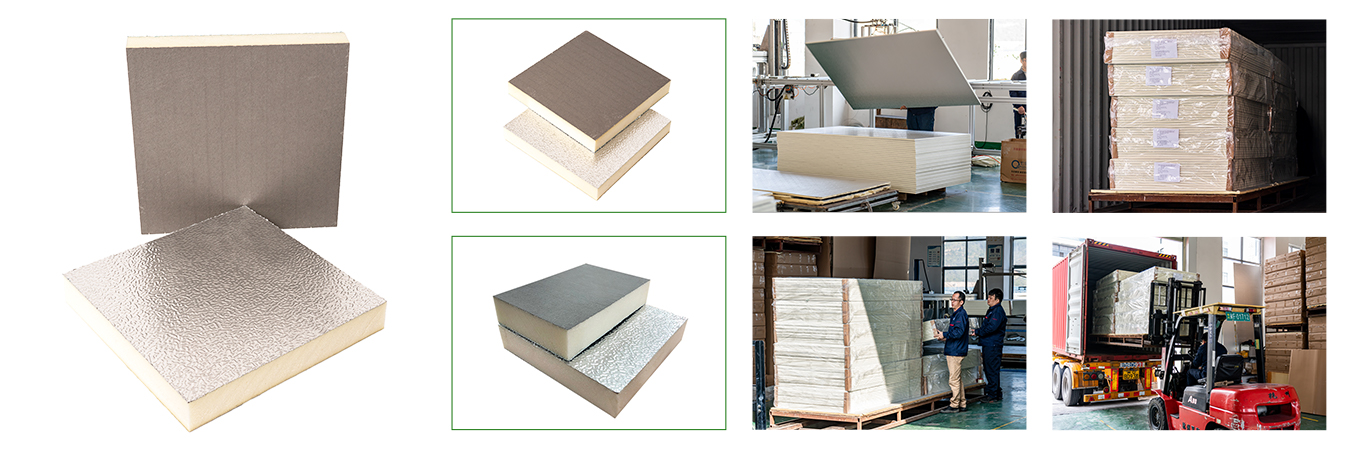

Polyurethane Foam Board consist of Polyurethane (PU) foam core, with a facing material of 80micron aluminum foil or fiberglass tissue laminated onto one or both sides. This aluminum foil acts as a barrier to moisture and enhances the PU insulation properties of the board. The standard width of Polyurethane Insulation Board is 1200mm or 600mm. The PU Board thickness and facing materials can be changed as per different application or project specifications. Polyurethane Board with aluminum foil surface has their excellent thermal performance, moisture and vapor barrier properties, durability, ease of installation, and environmental friendliness.

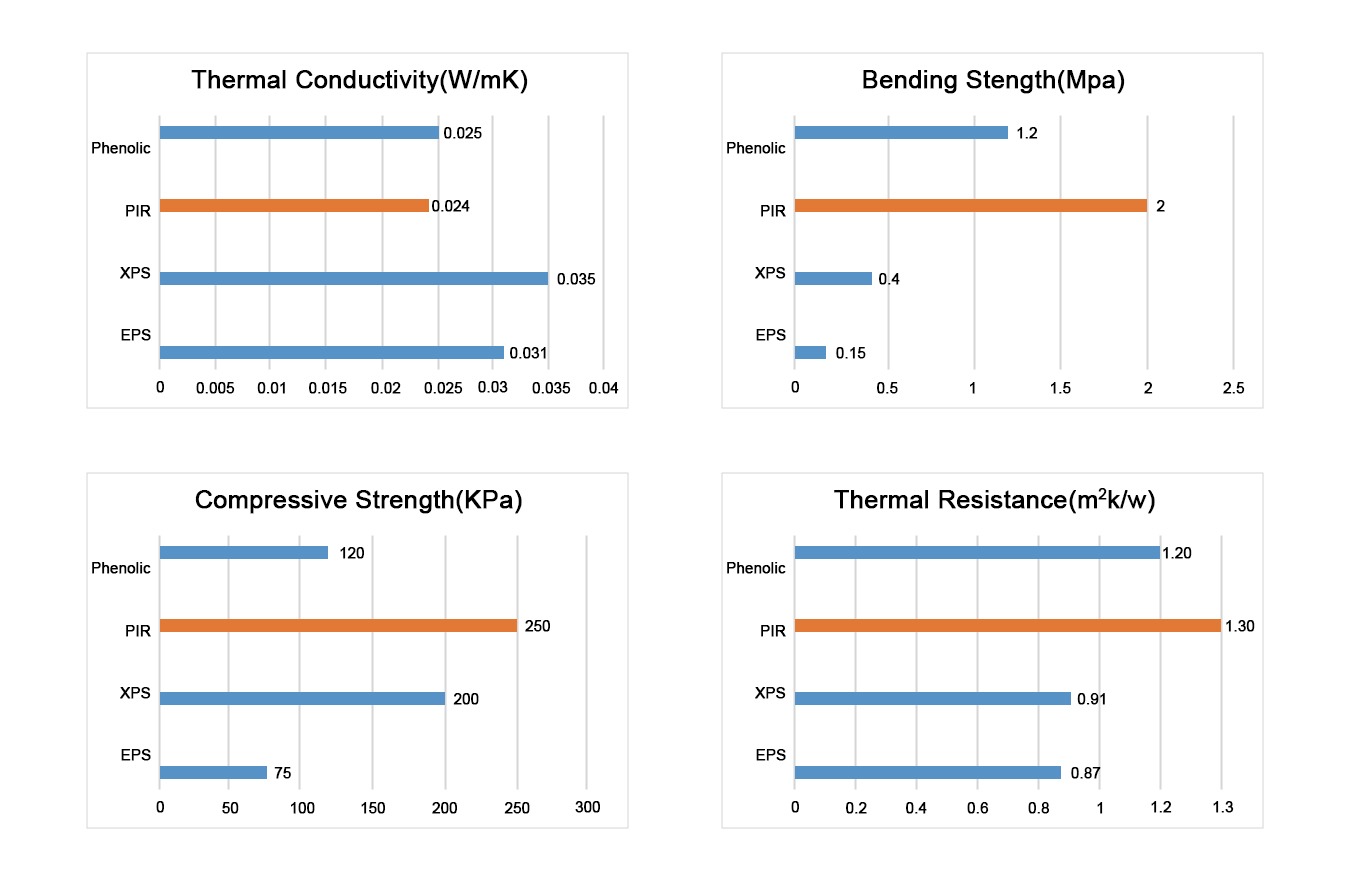

Technical Data Sheet

| Property | Standard | Specification |

| Standard Width | 600/1200mm | |

| Thickness | 10-80mm | |

| Foam Density | ASTM D1622/D1622M-14 | 30-50kg/m³ |

| CFCs and HCFCs | Headspace GC/MS | Free |

| Thermal Conductivity | ASTM C518-17 | <=0.024W/m.K |

| Fire Rating | BS 476 Part 6&7 | Class 0 |

| Compressive Strength | ASTM D1621-16 | >=0.15Mpa |

| Tensile Bond Strength | DB34/T 3826-2021 | >=0.15Mpa |

| Water Absorption by Volume | ASTM C209-15 | <3% |

| Dimensional Stability |

70ºC 48h<=1.5% -30ºC 48h<=1.0% |

|

| Service Temperature | DB34/T 3826-2021 | -30ºC – 120ºC |

Advantages of Polyurethane Foam Board with Aluminum Foil

Why Choose GFI Polyurethane Foam Board?

Application of PU Insulation Board

1.Wall Insulation Systems

- External Thermal Insulation Composite Systems (ETICS) : Recticel PU insulation boards serve as the primary insulation layer installed on the exterior walls of buildings, providing thermal insulation and reducing heat transfer through the walls.

- Internal Wall Insulation Systems : Used for insulating the internal walls of buildings, particularly suitable for retrofitting old buildings for energy efficiency without affecting the exterior appearance.

2.Roof Insulation

- Flat Roof Insulation : PU foam insulation board can be directly laid on flat roofs, creating a continuous insulation layer to prevent heat loss through the roof.

- Pitched Roof Insulation : Suitable for various forms of pitched roofs, easy to install, and enhances overall insulation performance.

3.Floor Insulation

- Underfloor Heating Systems : In underfloor heating systems, PU rigid insulation board effectively reduce downward heat loss, improving the energy efficiency of the heating system.

- General Floor Insulation : Used in regular floor structures to enhance insulation performance and improve indoor comfort.

4.Curtain Wall Insulation

- Glass Curtain Wall Insulation : Polyurethane insulation boards can be used as insulation material in glass curtain wall systems, improving the thermal insulation performance of the curtain wall and reducing energy loss.

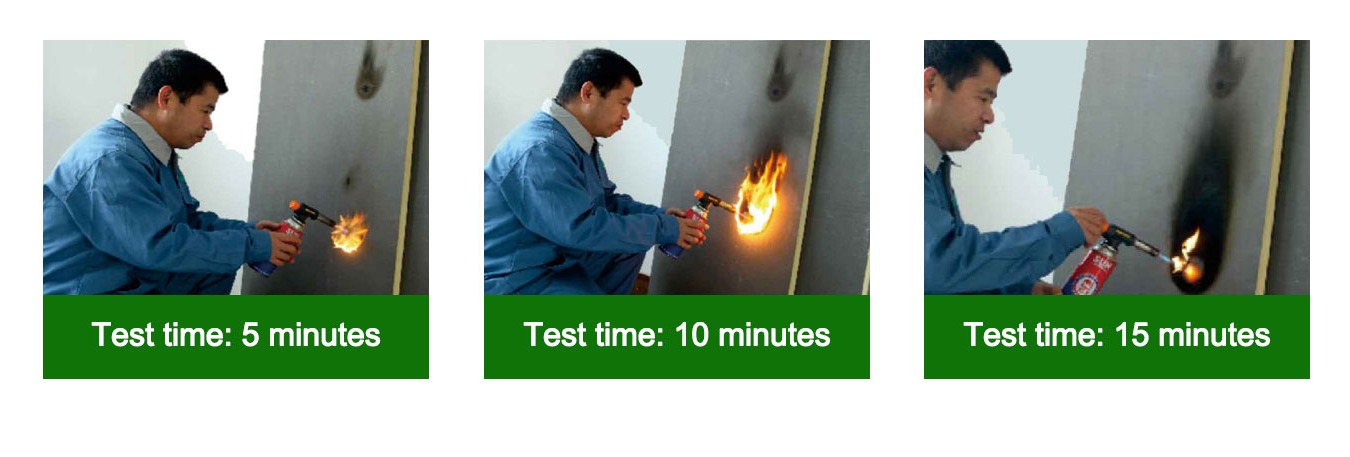

Buring Comparison Test

The following pictures show the state of the RLB-l polyurethane insulation fireproof composite board under the direct combustion of the 1300℃ flame torch for each period of time. During the entire experiment, the RLB-I polyurethane insulation board did not burn through and did not drip water. Prevent flame spread and heat conduction, no burning phenomenon.