Understanding the Optimal Density of PIR Foam Insulation Board

In the world of insulation materials, a common misconception persists: the higher the density, the better the thermal performance. This is often true for materials like glass wool, where increased fiber density enhances insulation. However, PIR (Polyisocyanurate) foam is fundamentally different in structure and behavior.

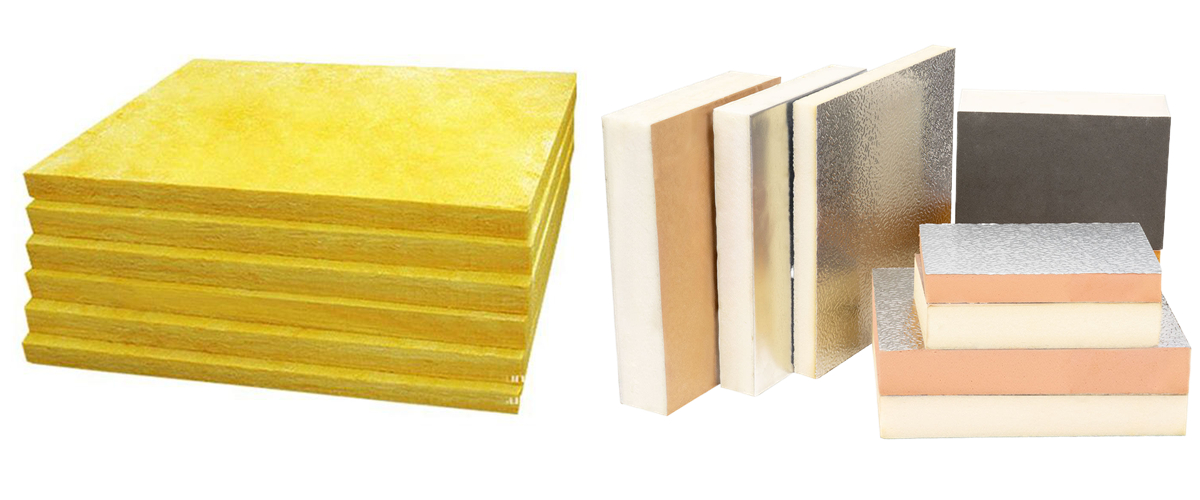

Structural Differences: Glass Wool Board vs. PIR Foam Board

Glass wool is an open-cell structure, composed of tangled fibers with numerous interconnected pores. The more densely packed the fibers, the more material there is to reduce heat transfer—hence better insulation.

PIR foam, on the other hand, is a closed-cell structure. It consists of tightly sealed air pockets distributed within a rigid polymer network. These microcells trap air, which itself is a poor conductor of heat. PIR's insulation performance relies not on density, but on the effectiveness of these closed cells in minimizing convection and radiation.

Why More Density Can Backfire

There’s a critical threshold when it comes to PIR foam insulation board density.

If the apparent density is too low (typically below 40kg/m³), the foam structure becomes too porous. Excessive voids may lead to internal air movement (convection) and reduced resistance to radiant heat transfer—resulting in higher thermal conductivity.

On the other hand, when density exceeds 50kg/m³, the volume of solid PIR polymer increases and the number of closed cells decreases. While mechanical strength may improve, thermal conductivity rises due to the denser structure—ironically reducing insulation efficiency.

Moreover, higher-density panels require greater thickness to achieve the same insulation effect, increasing material and installation costs.

The Concept of Optimal Density

For porous insulation materials, the best thermal performance is achieved not when density is highest, but when the combined effect of conduction, convection, and radiation heat transfer is minimized. This ideal condition is referred to as the optimal density.

GFI’s Recommendation: 40–50kg/m³ for Balanced Performance

Based on years of production experience and real-world engineering feedback, GFI recommends an optimal density range of 40–50kg/m³ for PIR foam insulation panels. This range ensures:

- Excellent thermal insulation performance

- Stable closed-cell structure with high cell integrity

- Good mechanical strength for wall and roof applications

- Cost-effective material usage with improved energy efficiency

Conclusion

When it comes to PIR foam insulation board, more isn’t always better. The ideal balance lies within the right density—not too low to lose structure, and not too high to compromise insulation. GFI Duct remains committed to providing high-performance PIR insulation solutions tailored to meet the specific energy-saving needs of modern buildings.

Need guidance on selecting the right PIR density for your project? Contact GFI Duct today for expert advice and customized solutions.