What Are The Advantages Of PIR?

Apart from minimizing the loss of warm or heated air, PIR insulation offers several other advantages:

Cost-Effectiveness: Although PIR boards are not the cheapest option compared to expanded or extruded polystyrene boards, they can reduce annual energy costs by up to 30%. This means their initial cost is quickly recouped, often within a few days.

Energy Efficiency: By retaining heat indoors, PIR insulation increases the energy efficiency of your home, helping to combat climate change and global warming.

Seasonal Versatility: In addition to maintaining indoor temperatures during winter, PIR boards help keep interiors cool in summer by reflecting heat away. This enhances the sustainability and energy efficiency of your building year-round.

Space-Saving: Compared to mineral wool insulation, PIR boards offer superior thermal insulation at a reduced thickness, saving valuable floor space. This is particularly beneficial for internal wall insulation.

Moisture Protection: The foil facings on PIR boards not only reflect heat and save energy but also act as a vapor barrier, protecting both the boards and the application from moisture intrusion.

Durability: PIR boards are highly resistant to moisture and do not sag over time, ensuring they retain their thermal performance long-term. This makes PIR insulation a reliable, long-term solution for insulation needs.

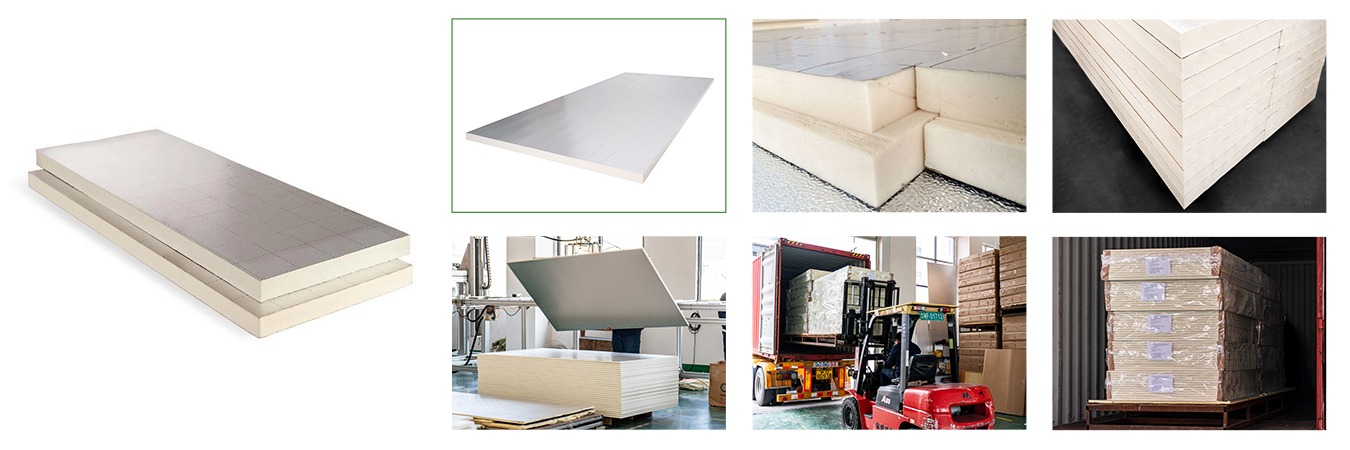

PIR Boards At GFI China

At GFI China, we produce PIR foam insulation board with fiberglass and aluminum foil surface, as well as kraft paper surface.

All of these PIR boards are made in standard with 1.2m wide, the length can be customized by customer requirements. These insulation boards have foil and fiberglass facings on either side. They are available in varying thicknesses to help suit any project type.

How To install PIR Boards?

PIR insulation can be installed using the Dot-and-Dab technique. Here’s a step-by-step guide:

Mark the Wall: Mark the ceiling and floor where the PIR boards will be installed. The markings should account for the board's thickness plus 10mm. For example, if the board is 50mm thick, make the markings at 60mm. Also, mark the center of the board on the wall and place horizontal markings every 1200mm to identify the board's margins.

Cut the Boards: Cut the boards to the appropriate size using a hand saw. Ensure the boards are 15mm shorter than the wall height.

Prepare the Adhesive: Mix the plasterboard adhesive, according to the manufacturer's instructions. Apply a continuous strip of adhesive to the edges of the ceiling, wall, and any openings like windows and doors.

Apply the Adhesive: Dab the adhesive onto the wall at 50-75mm intervals and 250mm-long strips. Each PIR board needs three vertical rows of adhesive, one in the middle and two on either side, at least 25mm from the edge.

Install the Boards: Press the back of the PIR boards against the dabs of adhesive while supporting them with plasterboard packers. Align the boards with the ceiling and floor markers, then tap them into place.

Secure the Boards: Use a board lifter to raise the PIR board tight to the ceiling. Remove the lifter once the board is fixed in place with plasterboard packers.

Seal the Joints: To prevent thermal bridging, tightly fit all boards together and secure the margins with foil tape.

The installation technique may vary depending on the location and specific use of the insulation.

In Conclusion:

Though EPS and XPS insulation boards act as effective alternatives to PIR insulation, there is no proper or more suitable alternative to PIR insulation in the market as yet. Its superior thermal insulation is what makes PIR a crowd favorite, and they are still in great demand in the construction industry.

For trade-quality PIR insulation boards, please visit GFI China. Choose GFI China's PIR insulation boards for superior energy efficiency and a sustainable future. Contact us now!