1 Challenges in HVAC Duct Installation and Corrosion Prevention

Ductwork is the core component of HVAC (Heating, Ventilation, and Air Conditioning) systems, directly affecting energy efficiency and long-term system stability. However, traditional HVAC duct installation faces multiple challenges, including:

- Inconsistent installation quality – Poor sealing and improper connections reduce airflow efficiency.

- Inadequate corrosion protection – Metal ducts exposed to high humidity, salt, or acidic environments are prone to corrosion, shortening their lifespan.

- Insulation damage – External insulation layers may be compromised due to installation or maintenance issues, increasing energy loss and condensation problems.

- Material quality concerns – The use of substandard duct materials leads to decreased durability and higher maintenance costs.

To address these challenges, the industry has focused on improving corrosion-resistant designs, insulation solutions, and material selection for HVAC ductwork.

2 Causes of Duct Corrosion in HVAC Systems

Corrosion is one of the key issues affecting the long-term performance of ductwork. The main causes include:

2.1 Environmental Factors

HVAC duct often operate in harsh environments, where various factors accelerate corrosion:

- Confined or underground spaces – High humidity and poor airflow contribute to condensation and corrosion.

- Coastal regions – Salt-laden air increases oxidation and accelerates metal corrosion.

- Industrial buildings – Chemical emissions, such as acidic or alkaline substances, promote material degradation.

2.2 Internal Air Quality Impact

The air transported through ducts can also affect corrosion, such as:

- High humidity – Moisture condenses on duct surfaces, forming a layer that accelerates electrochemical reactions.

- Chemical pollutants – Gases like SO₂ and NOx mix with moisture, creating acidic compounds that corrode duct interiors.

2.3 Installation and Material Issues

- Welding and connection defects – Poor welding quality and improper sealing create stress points, leading to localized corrosion.

- Low-quality metal materials – Inferior galvanized steel or inadequate coatings degrade over time.

- Insulation layer problems – If external insulation is not properly sealed, trapped moisture can accelerate corrosion.

To mitigate corrosion issues, pre-insulated ducts have gained widespread adoption due to their integrated insulation design and enhanced corrosion resistance.

3 Advantages and Applications of Pre-Insulated Ducts

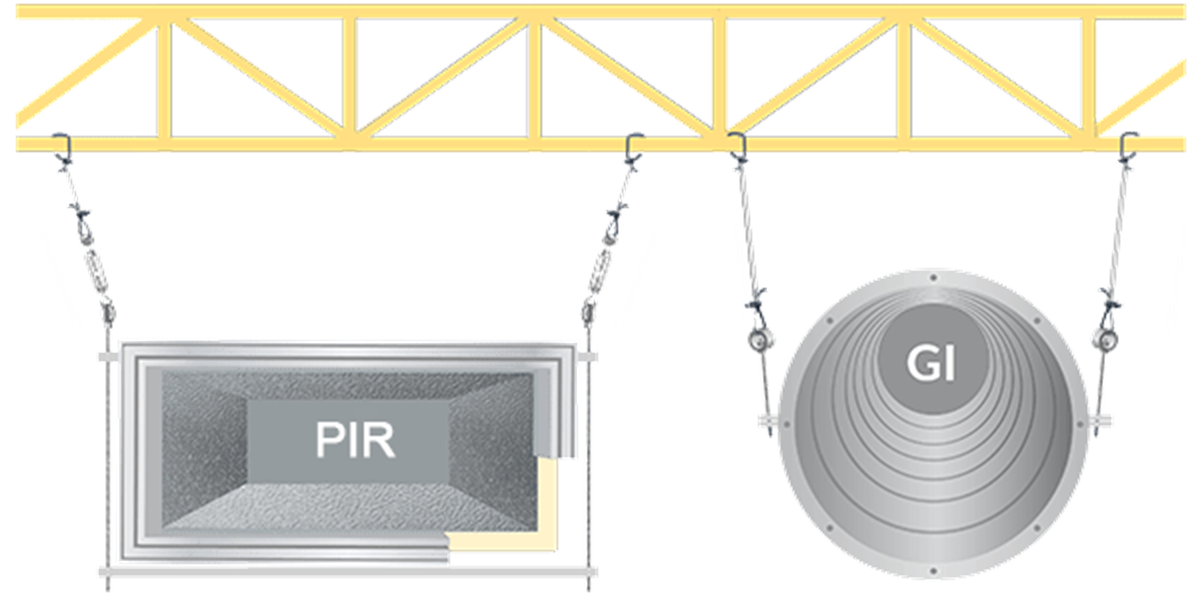

Pre-insulated ducts (PIDs) integrate insulation materials with duct structures, eliminating external insulation failures while significantly improving durability and performance. Common core materials include:

- 聚氨酯(PU) – Provides excellent thermal insulation with a closed-cell structure and moderate weather resistance.

- Polyisocyanurate (PIR) – Offers higher fire resistance and improved high-temperature stability compared to PU.

- Phenolic foam – Low smoke and toxicity with superior fire resistance, making it ideal for high-safety applications.

3.1 Key Features of Pre-Insulated Ducts

3.1.1 Enhanced Corrosion Resistance

Pre-insulated ducts often feature aluminum foil, galvanized steel, or stainless steel outer layers, reducing exposure to corrosive elements. Aluminum foil, for example, protects against acidic gases and extends duct lifespan by 2-3 times compared to conventional duct systems.

3.1.2 GFI PID Duct Superior Thermal Insulation

The core materials of pre-insulated ducts provide significantly lower thermal conductivity than traditional metal ducts with external insulation:

- PU duct thermal conductivity: ≤ 0.022 W/(m·K)

- PIR duct thermal conductivity: ≤ 0.021 W/(m·K)

- Phenolic duct thermal conductivity: ≤ 0.020 W/(m·K)

Compared to traditional galvanized steel ducts + external insulation, heat loss is reduced by 30%-40%, improving HVAC energy efficiency.

3.1.3 Lightweight Design for Easier Installation

Pre-insulated ducts weigh only 1/5 to 1/10 of conventional metal ducts, reducing structural load and installation complexity. Installation efficiency improves by 40% or more, lowering labor costs.

3.1.4 Sustainable and Eco-Friendly

Pre-insulated ducts support green building initiatives, reducing material waste and improving long-term energy efficiency. They comply with LEED, BREEAM, and other sustainability standards.

Construction personnel must possess necessary skills and knowledge, familiar with relevant processes and operating procedures. They should understand proper duct installation methods, joint treatments, insulation material installations, etc. Training sessions or professional institution support may be organized to enhance the professional level of construction workers and ensure quality construction.

4 Installation and Corrosion Prevention Strategies for Pre-Insulated Ducts

4.1 Pre-Installation Preparation

- Ensure all pre-insulated duct materials meet industry standards, particularly core density, aluminum foil thickness, and adhesive strength.

- Plan an optimized duct layout to minimize unnecessary joints and enhance system sealing.

4.2 Connection and Sealing Technologies

- Aluminum flange connections – Lightweight and easy to install, suitable for commercial and residential applications.

- PU foam joints – Provide superior airtightness, ideal for clean environments like hospitals and food processing facilities.

- TDF flange connections – Offer high mechanical strength for large-scale HVAC systems with high airflow rates.

4.3 Maintenance and Optimization

- Thermal performance assessments – Use infrared thermography to detect heat loss and ensure long-term energy savings.

- Regular duct cleaning – Prevent dust buildup that affects indoor air quality; clean ducts every 6-12 months.

- Seal inspections – Check joints and connections to prevent air leakage and maintain efficiency.

5 Conclusion

Duct corrosion remains a major challenge in HVAC Duct system performance and longevity. GFI Duct Pre-insulated ducts, with their integrated insulation, corrosion resistance, and lightweight design, offer a modern solution for commercial and industrial buildings. As energy efficiency and sustainability become global priorities, the adoption of pre-insulated duct technology will continue to grow, providing a more durable and cost-effective alternative to traditional ductwork.