How to Use Zinc-Coated Steel Hangers for HVAC Duct Installation

Zinc-coated steel hangers are an essential accessory for HVAC Duct installations, offering durability and reliable support. Their zinc coating provides excellent corrosion resistance, making them suitable for both residential and commercial projects. Here’s a step-by-step guide to using these hangers effectively:

1.Plan and Prepare

Start by examining the HVAC Duct system layout and identifying areas where support is necessary. Proper planning ensures optimal placement of the hangers, typically spaced 4 to 6 feet apart or as recommended by local building codes. Gather the required tools, such as a measuring tape, drill, screws, and the hangers themselves.

2.Mark the Installation Points

Measure and mark the locations on the ceiling or structural beams where the hangers will be installed. Accurate marking helps maintain alignment and balance throughout the Air Duct system.

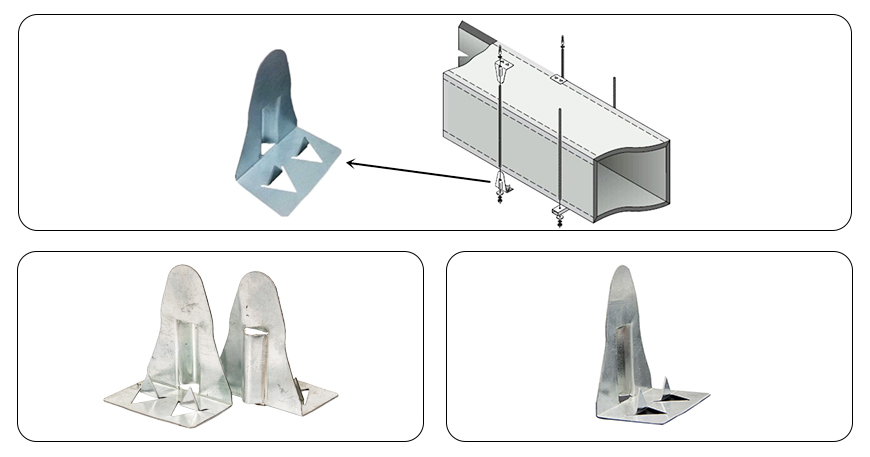

3.Install the Hangers

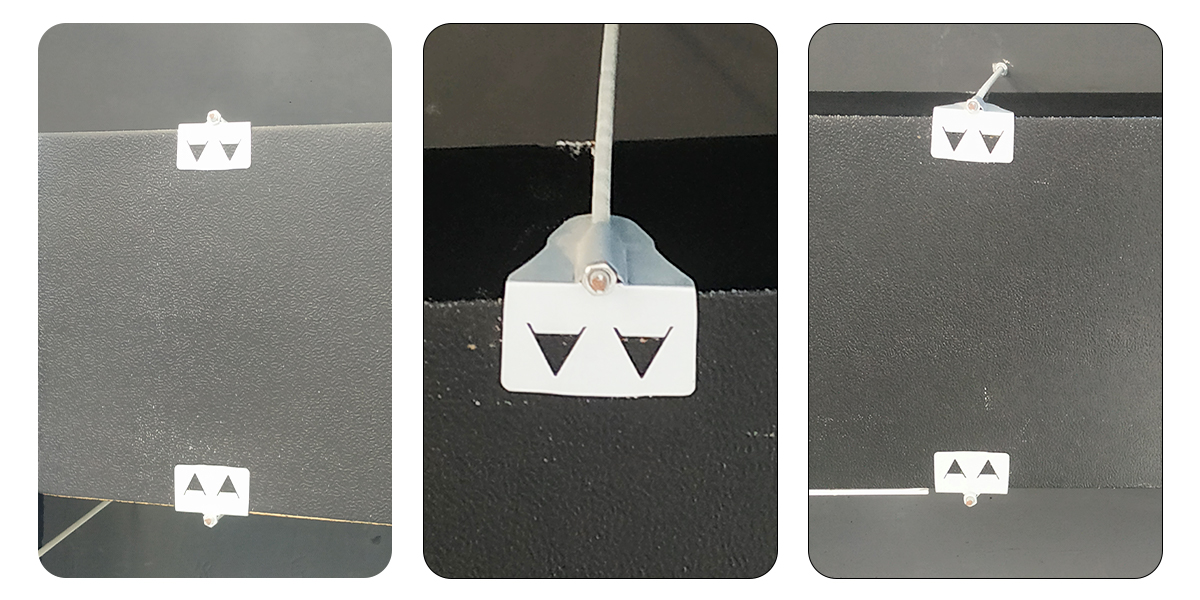

Using a drill or appropriate fasteners (Aluminum Reinforcement Section Bar), secure the zinc-coated steel hangers to the marked points. Ensure they are tightly fastened to the support structure of PIR air duct to prevent movement or loosening over time. The strength and corrosion resistance of these hangers make them ideal for long-term installations.

4.Position and Secure the Air Duct

Carefully position the PU Air Duct within the hanger loops or cradles. Adjust the hanger length or tension to ensure the pre-insulated air duct is leveled and properly aligned with the rest of the system. This step is crucial for maintaining airflow efficiency.

5.Inspect and Test

Once all hangers are in place, conduct a thorough inspection. Check for stability, proper alignment, and any signs of stress on the hangers or ducts.

Using zinc-coated steel hangers correctly ensures a stable and long-lasting HVAC duct system, promoting better performance and safety.